Digital transformation of the product information management process. Comprehensive implementation of a new approach to automate the PIM / MDM / DAM process.

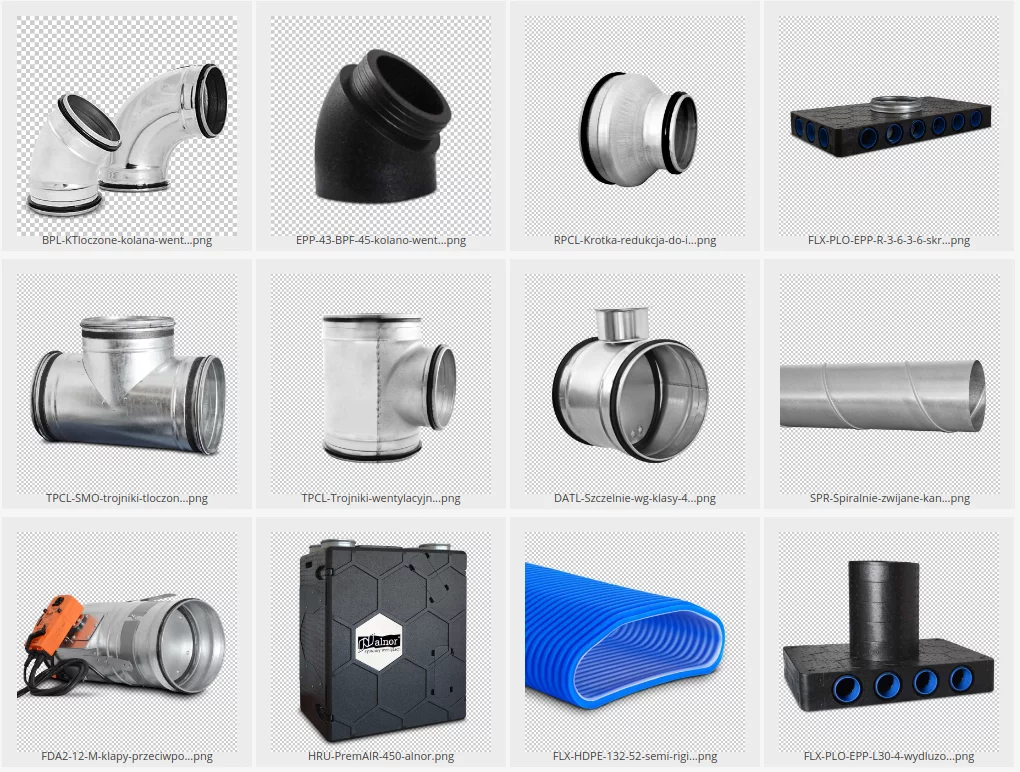

Poland's leader in the ventilation industry, a manufacturer and distributor of innovative ventilation systems for industry, commercial and domestic facilities worldwide. It offers a wide range of products, including ventilation ducts and fittings, air distribution systems, as well as components for insulation and installation of HVAC systems. The company places a strong emphasis on innovation and the quality of its products, making it a recognized supplier in the industry.

Project Summary

The implemented PIM system has become the main place for collecting data and digital resources for almost 100,000 products. It facilitates the work of Marketing, Sales, R&D and Logistics departments. On the basis of PIM, ETIM (European Technical Information Model) was implemented, which enables electronic data exchange with many countries and Partners. Ultimately, PIM will provide a Digital Product Catalog for the HVAC industry.

Challenge

Scattered product data in various sources, lack of a central product information management system, lack of a tool to control the quality and completeness of data. Manual, labor-intensive process of obtaining product data from many sources and updating them in various distribution channels, resulting in the risk of errors. A constantly growing large database of products, goods and raw materials with many features and technical parameters difficult to maintain without a single source of truth - a PIM system.

The main place for storing product information in the organization was the ERP system. The information in SAP is for the needs of warehouse management and some data for the B2B channel. The remaining data was collected in the form of files and PDF product catalogues; there was no central database collecting in one place in a structured way all data completed at each stage of the product life cycle.

Due to the large number of products, products and components, and the dispersion of product data, it was a challenge to maintain the current version of product data and quickly update this data in several places at the same time. In addition, all updates had to be done manually in several places, e.g. product catalogues, website, B2B system.

The main goal of implementing Pimcore was to provide a central repository of product data as the only source of truth for Alnor departments and distribution channels.

Solution

Implementation in Alnor PIMCORE, which includes PIM, DAM, MDM, CDM and Data Quality Management and Workflow, as a central product information management system, enabling the collection of all product data for over 100,000 products in one system and ensuring fast, efficient work related to with data maintenance, as well as delivering them to B2B, B2C, websites, distributors.

- The system enables controlled data enrichment, quality assurance, automatic downloading and synchronization of data with the ERP system. It was also provided with data from the so-called "non-obvious" sources such as MODX and IDML through the use of ETL processes.

- The system has mechanisms that automate and accelerate work on product information.

- Implementing PIMCORE ensures the ability to send data from one place to many distribution channels - without the need to manually enter it in several places.

- PIMCORE constitutes a fundamental basis for further implementation of Alnor's digital transformation through the possibility of integration with many diverse distribution channels.

Results

Central trusted source of product information

The introduction of Pimcore provided a central, comprehensive source of product data and contributed to the automation of many processes related to product information management. It is a tool for maintaining high data quality through systemic control of deficiencies and data quality management. The implemented system reduces the time and costs of work related to the creation, publication and maintenance of product data.

The implementation of Pimcore will enable further development of the online product catalog, positively influencing communication with Partners not only from Poland but also from many foreign markets, including: by implementing the ETIM classification and the ability to maintain data in many languages. The system will be constantly developed, including: in order to automate marketing and sales processes in the HVAC industry, serve B2B and B2C customers and distribute product information to various e-commerce channels.